Understanding Bills of Materials (BoM) in Odoo

A Bill of Materials (BoM) is an essential document in manufacturing that defines the quantity of each component needed to produce a finished product and includes routing details for the manufacturing process.

In Odoo, you can link multiple BoMs to a product, manage product variants, and improve efficiency in your production workflow. This guide will walk you through setting up a BoM, using it for product variants, adding routing, and managing by-products.

Setting Up a Bill of Materials in Odoo

BoMs can be used without routings, which means manufacturing operations are managed using a single manufacturing order. This approach is suitable when production is done in one step, without tracking individual operations.

Following are the steps to create a BoM in Odoo:

1. Create the required products

Before setting up a BoM, make sure the finished product and components are created in Odoo.

- Go to Master Data → Products.

- Create both the finished product and at least one component.

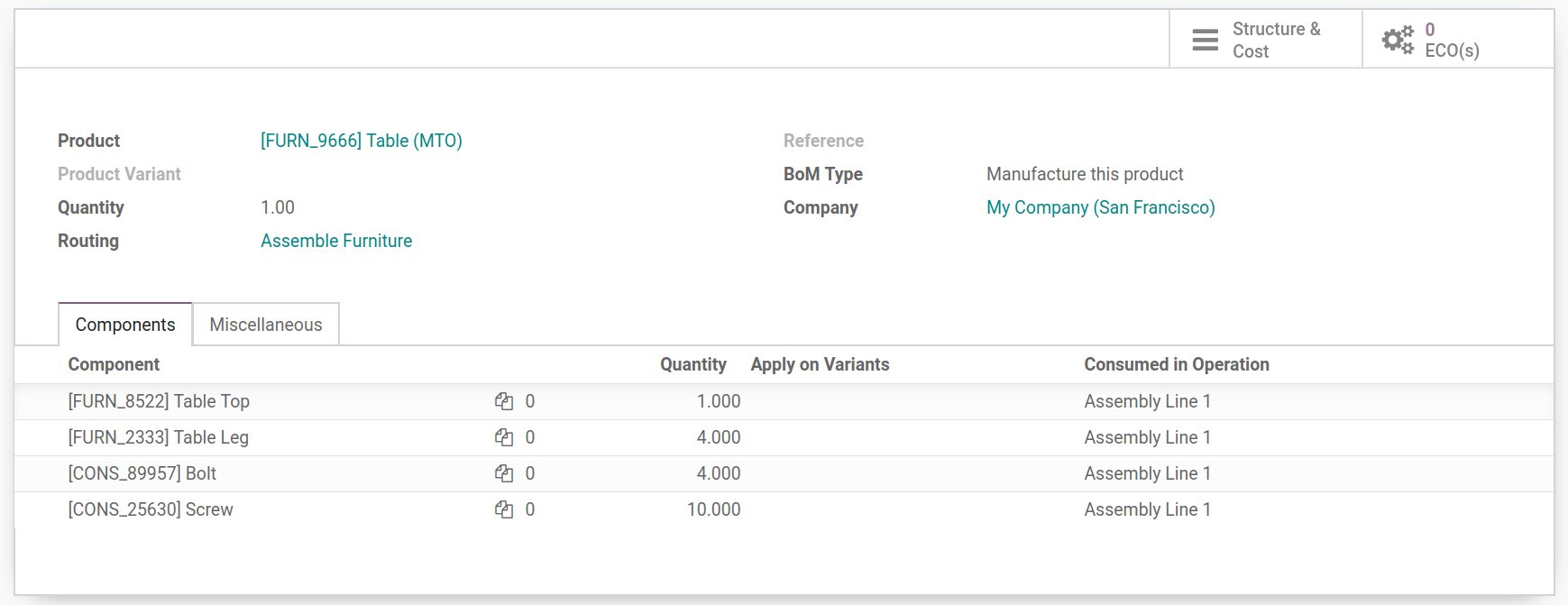

2. Create the Bill of Materials

- Navigate to Master Data → Bills of Materials.

- Click Create.

- Select the product from the dropdown menu.

- Add the components and their quantities.

By default, Odoo sets the BoM type to “Manufacture this Product”, which is suitable for standard production workflows.

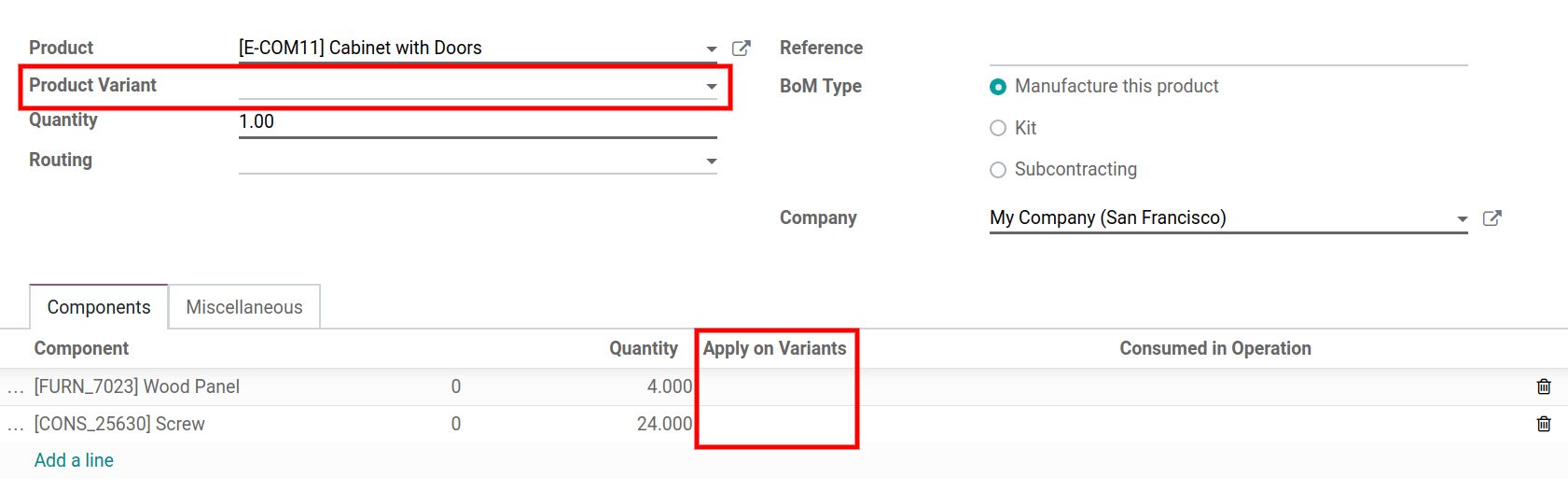

Using the Same BoM for Product Variants

Odoo allows you to manage product variants within a single BoM. If a product has multiple variants, you can specify which variant a BoM applies to.

- If the BoM is for one variant, select it in the Product Variant field.

- If multiple variants share a BoM but use different components, specify the corresponding variant for each component line.

This flexibility ensures that the correct materials are used for each product version without creating separate BoMs.

Adding a Routing to a BoM

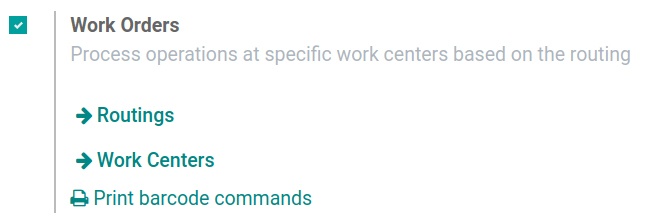

Routing is used when a manufacturing process involves multiple steps. If your production process requires work operations, you’ll need to enable Work Orders in the Manufacturing app settings before adding routing to a BoM.

Key points about Routing in BoMs

- Each BoM can have only one routing.

- A single routing can be used in multiple BoMs.

Once routing is created, add it to the BoM. You can also specify at what stage in the production process each component is used.

Adding By-Products to a BoM

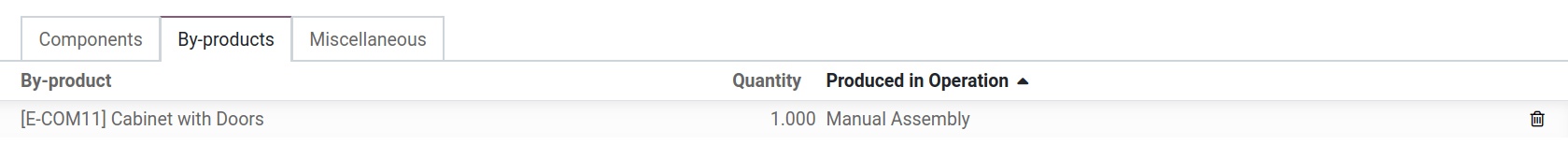

In some manufacturing processes, additional products are produced alongside the main product. Odoo allows you to define By-Products within a BoM.

How to Add By-Products in Odoo

- Enable By-Products in Manufacturing app settings.

- Open the BoM and add By-Products under the By-Products section.

- Define at which operation the by-product is produced.

There’s no limit to the number of by-products you can add, making tracking all outputs from a production process easier.

Learn More About Odoo Manufacturing

Check out our Complete Odoo Manufacturing Guide for an in-depth walkthrough of all key features.

Wrapping Up

Setting up a Bill of Materials correctly is crucial for efficient manufacturing. Whether you're managing standard production, product variants, or multi-step processes, Odoo provides flexible options to suit different workflows.