Product Disassembly in Odoo 17

The process of disassembling a product involves removing its individual parts. In certain exceptional circumstances, a manufacturing enterprise may find it necessary to disassemble a product, which may occur as a result of procurement activities. Maintaining accurate records of such disassembled orders is imperative in these scenarios. The Odoo 17 Manufacturing platform facilitates the creation of disassembled orders for previously manufactured products.

Why Should Manufacturing Facilities Un-build a Product?

- Reclaim damaged parts or raw materials.

- Handle product returns.

- Repurpose parts for new manufacturing.

- Adjust inventory levels.

- Reassemble parts for new products if defects are found.

- Accurately record deconstructed materials and components.

Benefits of Product Un-building in Odoo 17

- Maintains accurate inventory levels, reducing waste and optimising resource use.

- Saves costs by salvaging valuable components from defective or returned products.

- Supports sustainability by minimising waste and promoting material reuse.

- Enhances traceability by linking disassembly orders to the original manufacturing orders.

How to Un-build a Manufactured Product

To begin the un-building process in Odoo 17, follow these steps:

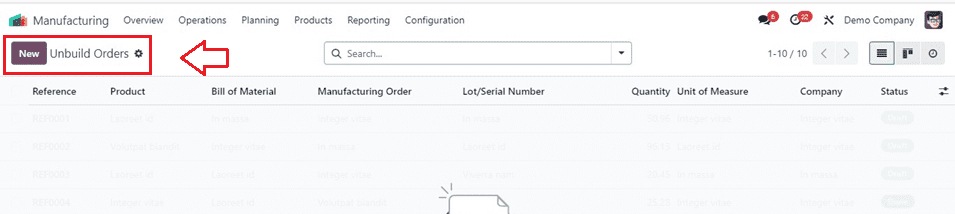

1. Go to the "Un-build Orders" option within the "Operations" menu. This provides a dedicated interface for managing un-build orders independently, allowing you to create un-build orders for acquired goods.

2. In the "Un-build Orders" interface, you'll see a dashboard displaying order references, products, bills of materials (BoMs), manufacturing orders, lot/serial numbers, quantity, unit of measure, company, and status for each un-build order.

3. To create a new un-build order, click the "New" button. This opens a configuration form where you can input details such as the un-build order name, product, bill of materials, quantity, manufacturing order, source location, destination location, lot/serial number, and company information, as shown below:

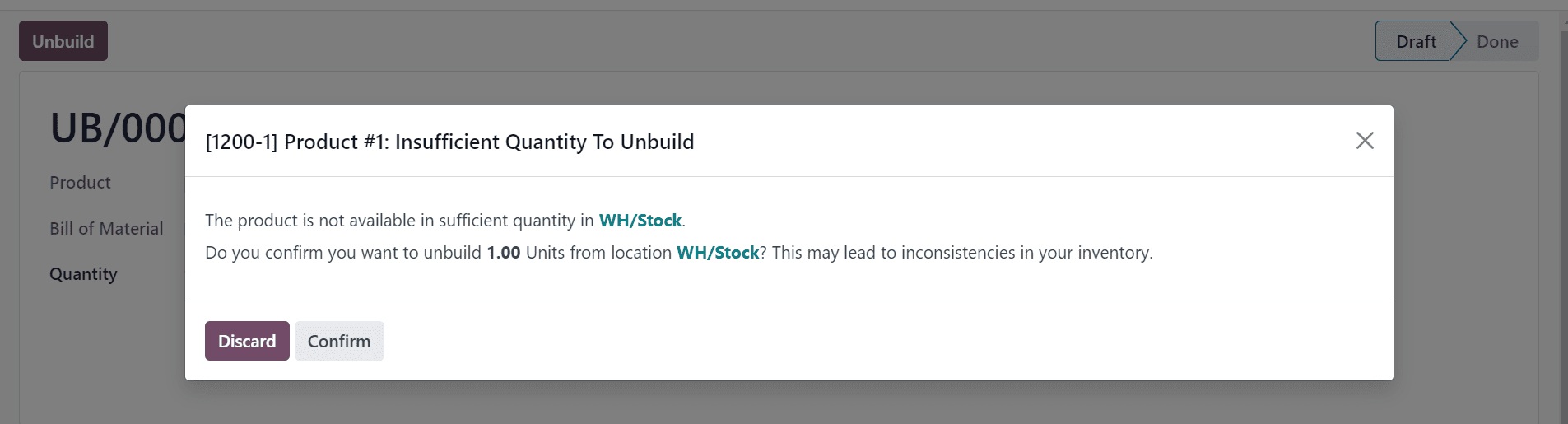

4. Once the configuration is complete, click the "Unbuild" button to initiate the disassembly process.

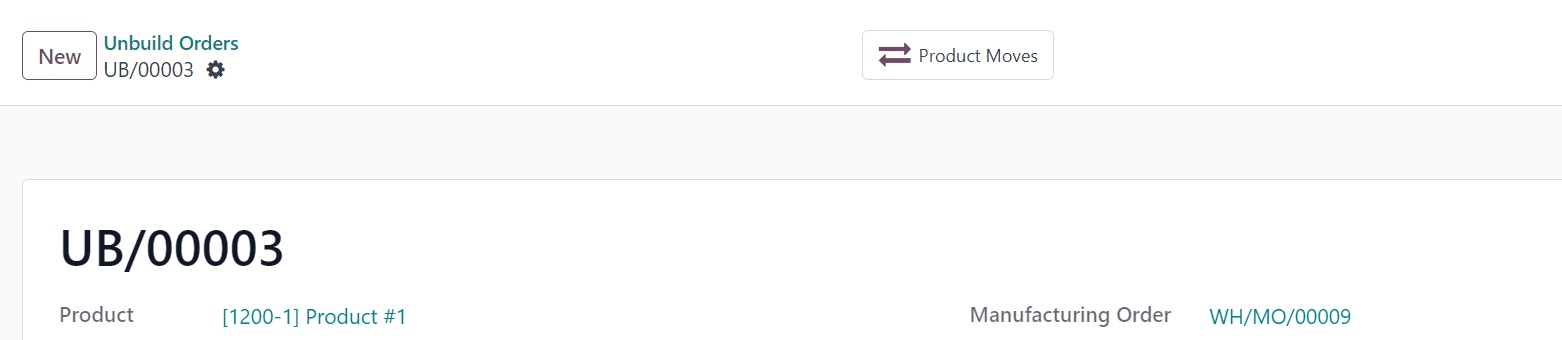

5. The un-build order is stored in the Odoo database. A "Products Move" smart button will appear in the configuration form, giving you access to a dashboard that details every component used in the disassembled product.

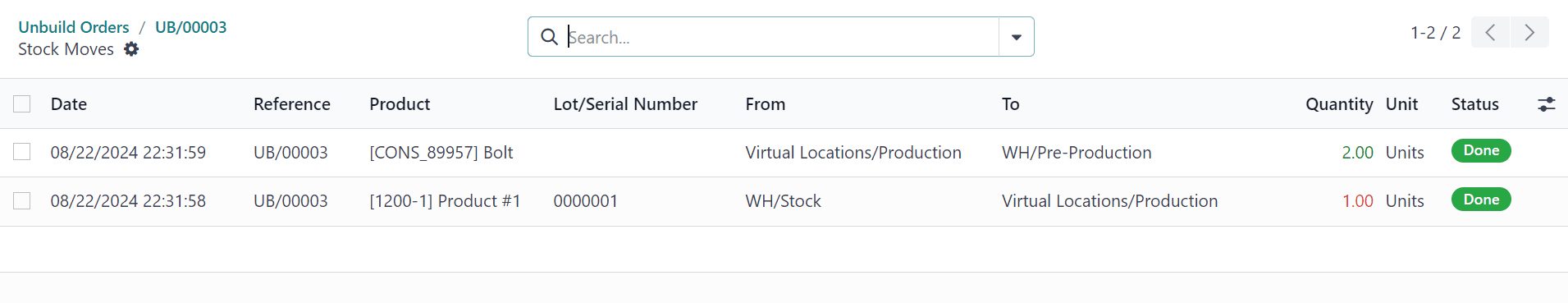

Tracking Un-build Orders

The "Product Moves" dashboard provides comprehensive details, including the un-building date, reference, product, lot/serial number, quantity, and unit for each component. Additionally, the newly created un-build order can be managed directly from the "Un-build Orders" dashboard.

Wrap-Up

The un-build feature is one of the most valuable tools in Odoo 17's Manufacturing module for inventory management, quality control, and reverse logistics. The ability to dismantle a product ensures that companies can efficiently recover and recycle essential resources, whether dealing with faulty goods, customer returns, or component reuse.