Efficient BoM Management in Odoo

A well-structured Bill of Materials (BoM) is key to efficient manufacturing. Odoo makes it easy to manage BoMs for product variants, semi-finished products, and flexible component consumption, allowing businesses to streamline their production process. This guide walks you through these features and how to configure them for better manufacturing efficiency.

Managing BoMs for Product Variants

If your products come in different variants (e.g., size, color, or material), Odoo lets you use a single BoM to manage them all. Instead of creating separate BoMs for each variant, you can define which component lines apply to which variant. This keeps things simple and reduces redundancy.

How to Set It Up

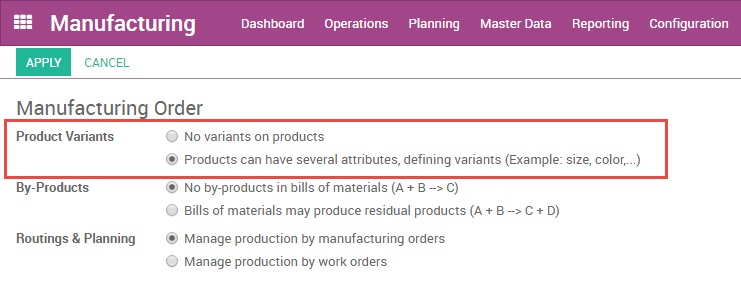

Enable Variants

Go to Configuration → Settings and enable Product Variants.

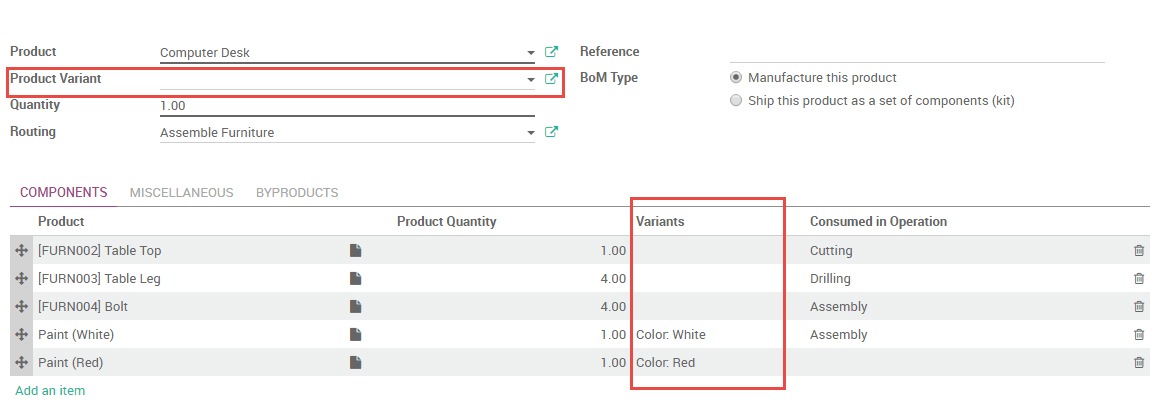

Create or Edit a BoM

- Add the components as usual.

- Specify which variants should use each component. If no variant is selected, the component applies to all variants.

Leave the Product Variant Field Blank

If you’re defining BoM components per variant, do not select a specific variant in the main BoM section. That field is only used when a BoM applies to a single variant.

This setup allows Odoo to automatically adjust component selection based on the chosen variant when a manufacturing order is created.

Managing Semi-Finished Products (Multi-Level BoMs)

Sometimes, manufacturing a product requires assembling smaller components first. These subassemblies (semi-finished products) have their own BoMs and must be produced before the final product. Odoo handles this with multi-level BoMs.

How Multi-Level BoMs Work

Subassembly BoM

Defines the components and process for producing the semi-finished product.

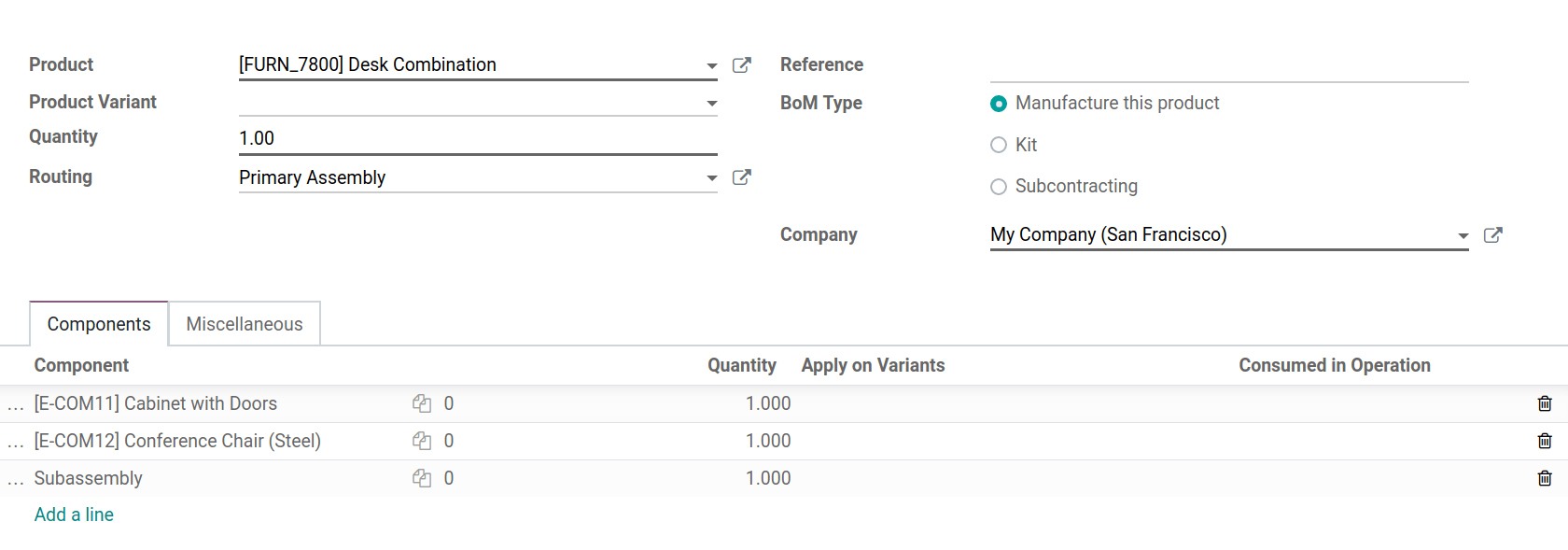

Main BoM

Includes the subassembly as a component in the final product.

Automatic Manufacturing Orders

When you create a manufacturing order for the final product, Odoo will also generate an order for any required subassemblies.

How to Set It Up

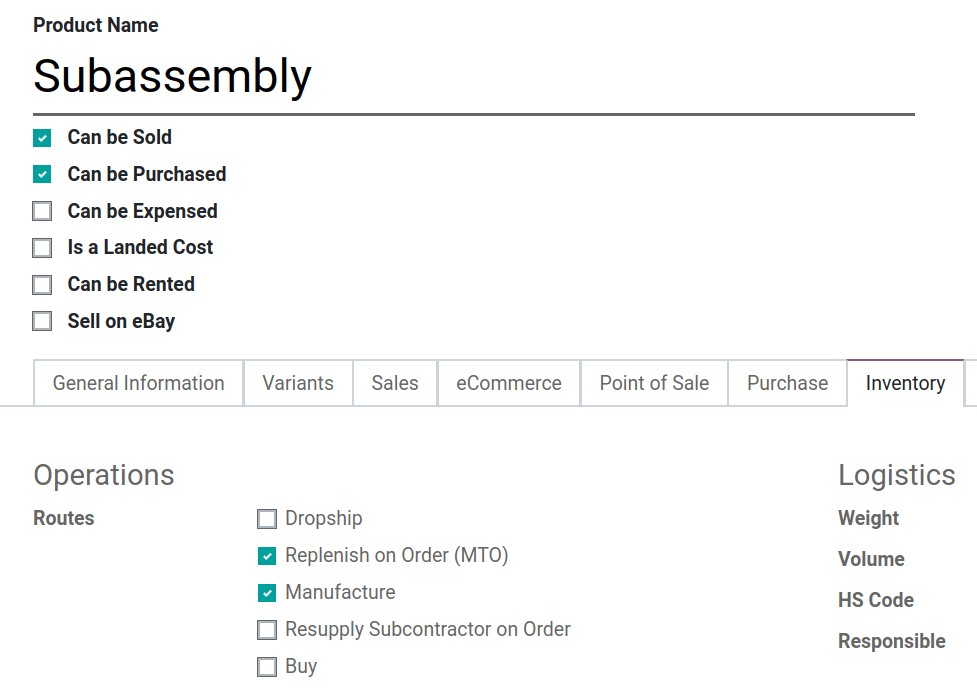

Create a Subassembly Product

- Go to the Products menu and create a product form for the subassembly.

- Enable Manufacture and Replenish on Order in the Routes section.

- Save the product.

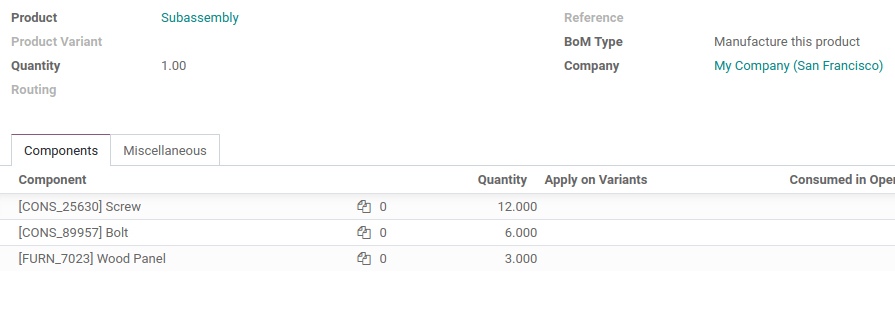

Define a BoM for the Subassembly

- In Manufacturing → Bill of Materials, create a new BoM.

- Select the subassembly product and add its components.

Configure the Main BoM

- Create a BoM for the final product.

- Add the subassembly as a component.

- Save your changes.

Now, when you manufacture the final product, Odoo will ensure that any required subassemblies are also produced first.

Using Flexible Component Consumption

Manufacturing doesn’t always go as planned. Sometimes, you might need to use more or fewer components than expected. Odoo’s Flexible Component Consumption feature allows you to adjust component usage on the fly.

When to Use It?

- Your customer requests a modification (e.g., one extra desk in a furniture set).

- Some components are damaged, and replacements are needed.

- You need to adjust material usage based on real-time production needs.

How to Enable Flexible Consumption

Activate Quality Control

Go to MRP app settings and enable the Quality feature.

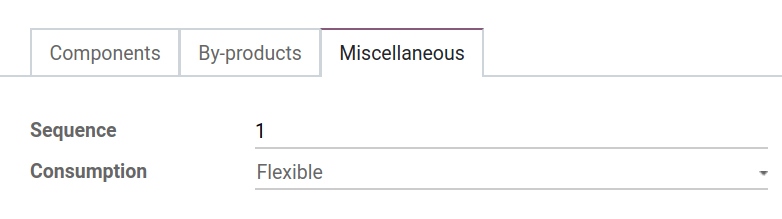

Edit the BoM

- Open the BoM for the product that needs flexible component usage.

- In the Miscellaneous tab, set Consumption Type to Flexible.

- Save the changes.

Set Up a Quality Control Point

- In the Quality app, go to Control Points.

- Create a new Quality Control Point.

- Select the product, operation, and work order.

- Set the type to Register Consumed Materials.

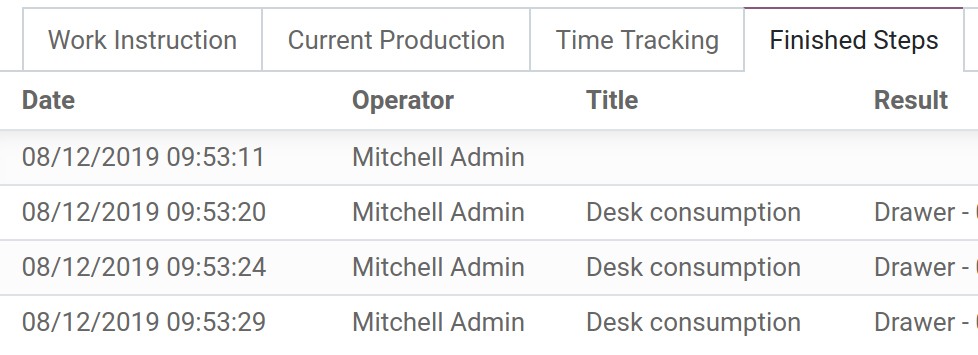

Use It in a Manufacturing Order

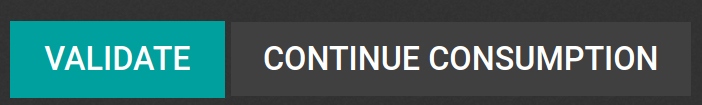

- Start a new Manufacturing Order for the product.

- During the process, click Continue Consumption to add extra components if needed.

- Once finished, review component usage under Finished Steps in the Work Order.

This feature gives you more flexibility in managing materials and ensures accurate tracking of actual usage.

Learn More About Odoo Manufacturing

Check out our Complete Odoo Manufacturing Guide for an in-depth walkthrough of all key features.

Wrapping Up

Odoo’s BoM features make it easier to manage complex manufacturing processes. Whether you’re handling product variants, assembling semi-finished products, or needing flexibility in material consumption, these tools help you maintain efficiency and reduce errors. By setting up your BoMs correctly, you can ensure a smooth manufacturing process.