Streamlining Work Orders with Odoo

Efficiently planning work orders is crucial for smooth manufacturing operations. Odoo's Manufacturing module allows companies to schedule work orders, prevent overlaps, and optimise resource allocation. This guide covers how to configure and manage work orders, including using alternative work centers for better flexibility.

Scheduling Work Orders in Odoo

Manufacturing companies often need to plan their work orders to organise daily production and prevent bottlenecks. With Odoo, you can schedule a Planned Start Date for your manufacturing orders, ensuring that work orders are executed sequentially. If two work orders are planned at the same work center and time, Odoo automatically schedules the second one after the first, avoiding scheduling conflicts.

How to Create Work Orders in Odoo

To start managing work orders, follow these steps:

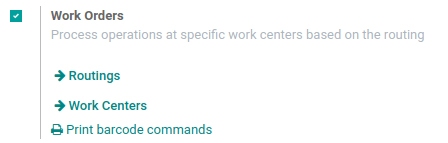

Enable Work Orders

- Open the Manufacturing app.

- Go to Settings and enable the Work Orders feature.

- Click Save.

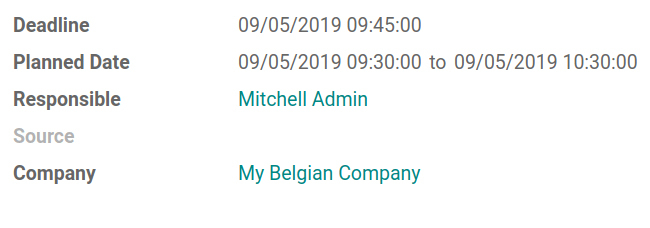

Create a Manufacturing Order

- Navigate to the Manufacturing Orders menu and click Create.

- Select the Product and set a Planned Start Date.

Note: The Deadline Start field is informational, indicating the latest possible time to begin production while meeting demand.

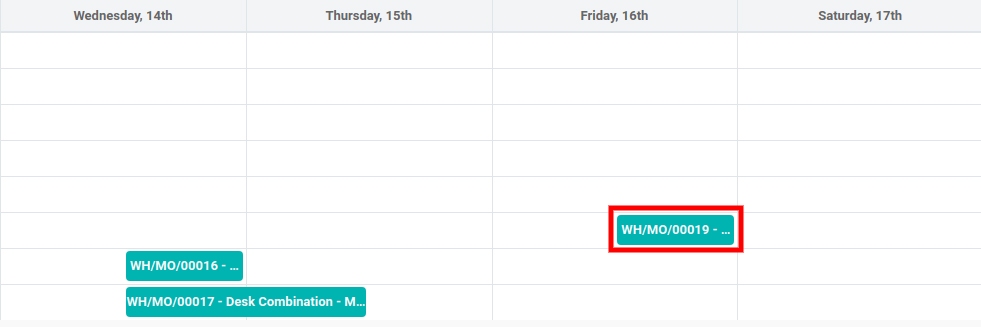

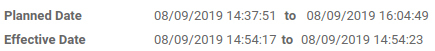

Plan and Track Work Orders

- Mark the Manufacturing Order as To Do and plan it.

- In the Planning menu, view scheduled work orders.

- If a work order starts later than planned, its delay is recorded in the Time Tracking tab.

Learn More About Odoo Manufacturing

Check out our Complete Odoo Manufacturing Guide for an in-depth walkthrough of all key features.

Using an Alternative Work Center

In real-world manufacturing, multiple products may need to be produced simultaneously at the same work center. Odoo allows you to assign alternative work centers to ensure production continues smoothly without bottlenecks. This feature enables:

- Efficient job tracking by recording which work center was used and when.

- Better scheduling for machine maintenance.

- Reduced downtime by automatically shifting work to alternative centers when necessary.

How to Configure Alternative Work Centers

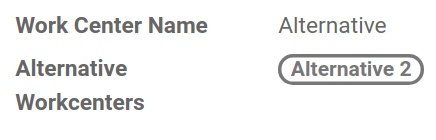

Set Up Work Centers

- With Work Orders enabled in the settings, go to Master Data > Work Centers.

- Create two new Work Centers.

- Set one as the alternative for the other and vice versa.

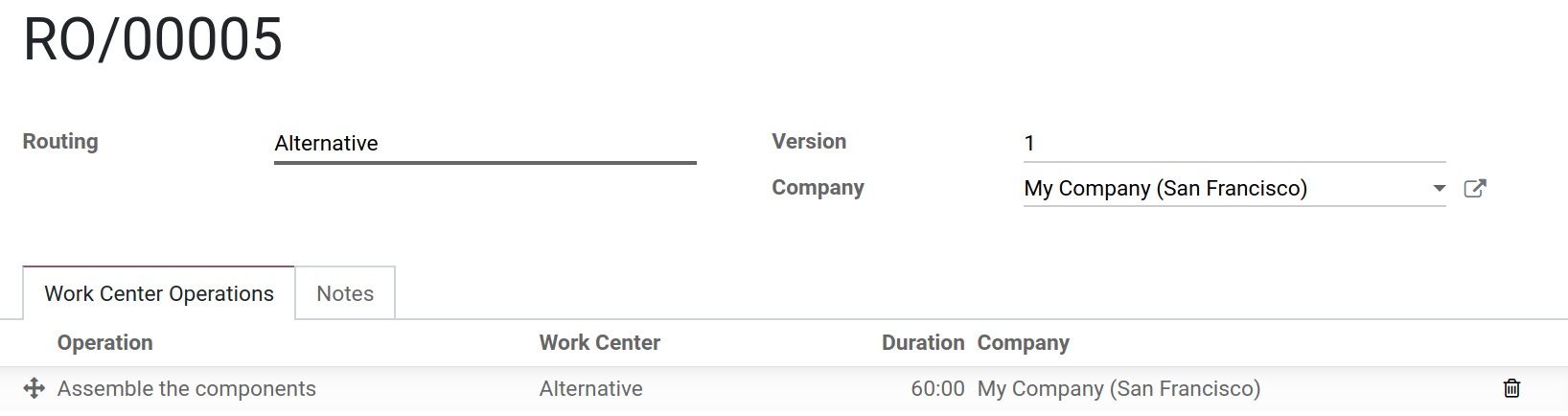

Define Routing

- Create a Routing and assign the work center.

- Add an operation and save the routing.

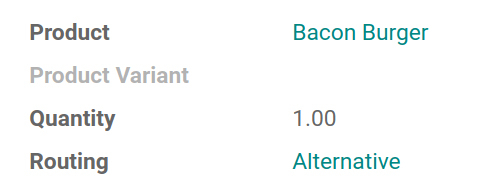

Configure Bill of Materials (BoM)

Create a Bill of Materials and assign the necessary components and routing.

Creating Work Orders with Alternative Work Centers

Once everything is set up, follow these steps:

Create a Manufacturing Order

- Navigate to Manufacturing Orders and click Create.

- Add the product and plan it.

Automatically Schedule Alternative Work Centers

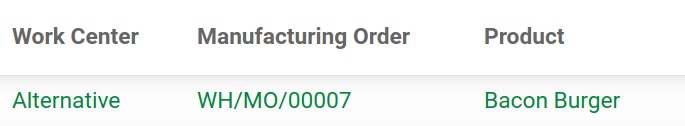

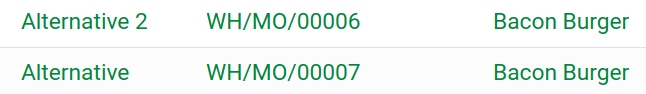

If a new work order is created while another is in progress, Odoo assigns it to the alternative work center.

Note: If post-production time is added to a work center, Odoo may still schedule work orders to an alternative center, even if the main one is available.

By leveraging Odoo’s Work Orders and Alternative Work Centers features, manufacturers can efficiently schedule, track, and optimise production. This reduces delays, prevents conflicts, and improves overall productivity.