Manufacturing Orders in Odoo

In Odoo, manufacturing orders can be managed in two ways: a simple, single-step process or a more detailed workflow with multiple steps. The choice depends on the level of control and tracking you need for your production process.

If you prefer a straightforward approach, Odoo allows you to manage everything within a single manufacturing order. You only need to schedule the job and record production—no additional steps or complexity.

However, if you need more visibility and control, you can break the manufacturing order into multiple steps using Work Orders and Routings. This method helps define precise sequences of operations, making it easier to schedule tasks, track efficiency, and analyse production performance.

Managing Manufacturing Without Routings

For simple manufacturing workflows that take place in a single location, involve one person, and require only one step, manufacturing orders without routings are the ideal choice. This is Odoo’s default setting.

When working this way, the manufacturing process consists of two basic phases:

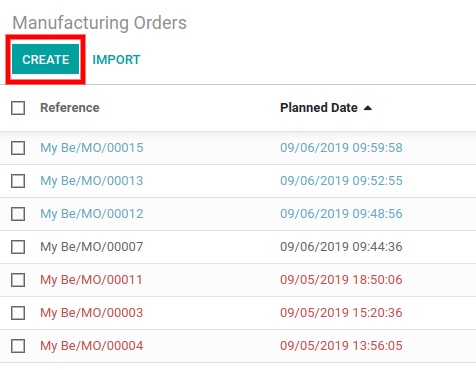

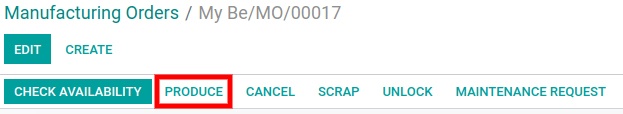

- Create a Manufacturing Order – Define the product and required components.

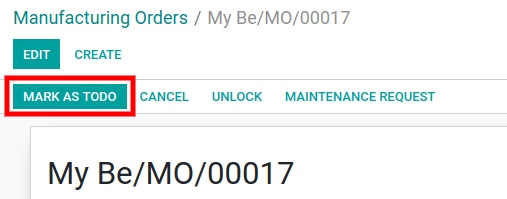

- Record the Production – Confirm and log the completion of the manufacturing process.

Managing Manufacturing with Routings and Work Centers

For more complex production processes, Odoo allows you to use Routings and Work Centers.

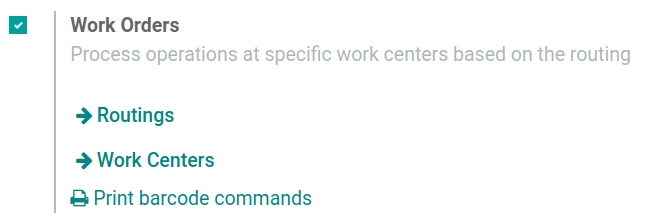

To activate this functionality, navigate to the Manufacturing app settings and enable the Work Orders feature.

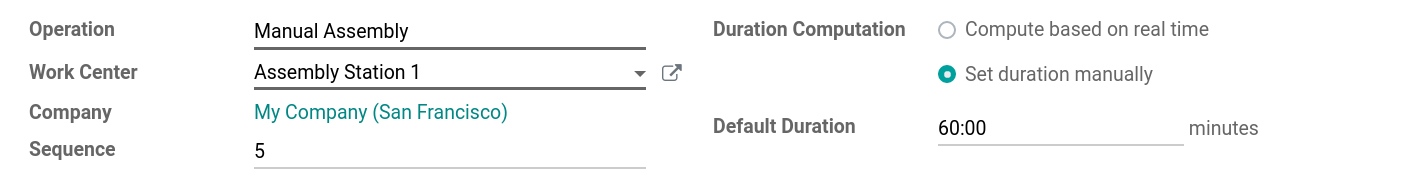

With this feature turned on, you can add routings to Bills of Materials (BoMs) and define operations that take place at different Work Centers. A Work Center represents a specific location where work orders are executed.

When manufacturing with routings and Work Centers, each Work Order is scheduled individually. This setup provides detailed insights, including:

- Time and capacity planning

- Costing report

- Efficiency analysis for each Work Center

The workflow in this case involves three key phases:

1. Create the Manufacturing Order – Define the product, components, and required operations.

2. Schedule the Work Orders – Assign tasks to specific Work Centers.

3. Perform the Scheduled Work and Record Production – Execute each step and log progress.

Learn More About Odoo Manufacturing

Check out our Complete Odoo Manufacturing Guide for an in-depth walkthrough of all key features.

Selecting the Best Manufacturing Approach

Whether you opt for a simple manufacturing order or a more structured approach with routings and Work Centers, Odoo provides the flexibility to fit your production needs. For small-scale or straightforward processes, a basic manufacturing order is sufficient. However, for more detailed tracking and efficiency analysis, using Work Orders and Work Centers ensures greater control over production.

By setting up the right workflow, you can optimise manufacturing operations, streamline scheduling, and gain better insights into production performance.