How Does MPS Work in Odoo?

The Master Production Schedule (MPS) is a powerful tool in Odoo Manufacturing that helps businesses plan their production based on demand forecasts. By using MPS, manufacturers can efficiently manage stock levels, replenishments, and production schedules while ensuring that demand is met without excess inventory.

This guide walks you through configuring the MPS, estimating demand, launching replenishments, and interpreting MPS data.

Step 1: Configure the Master Production Schedule

Before using the MPS, it must be activated in the Manufacturing app:

- Go to Manufacturing → Configuration → Settings.

- Enable the Master Production Schedule option.

- Click Save.

Tip: In the Manufacturing settings, you can define the time range (month/week/day) and set the number of periods you want to display in the MPS view.

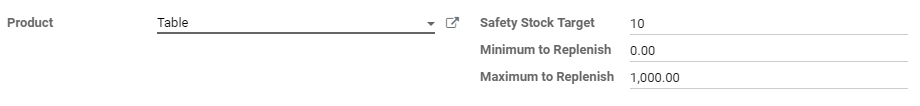

Adding Products to the MPS

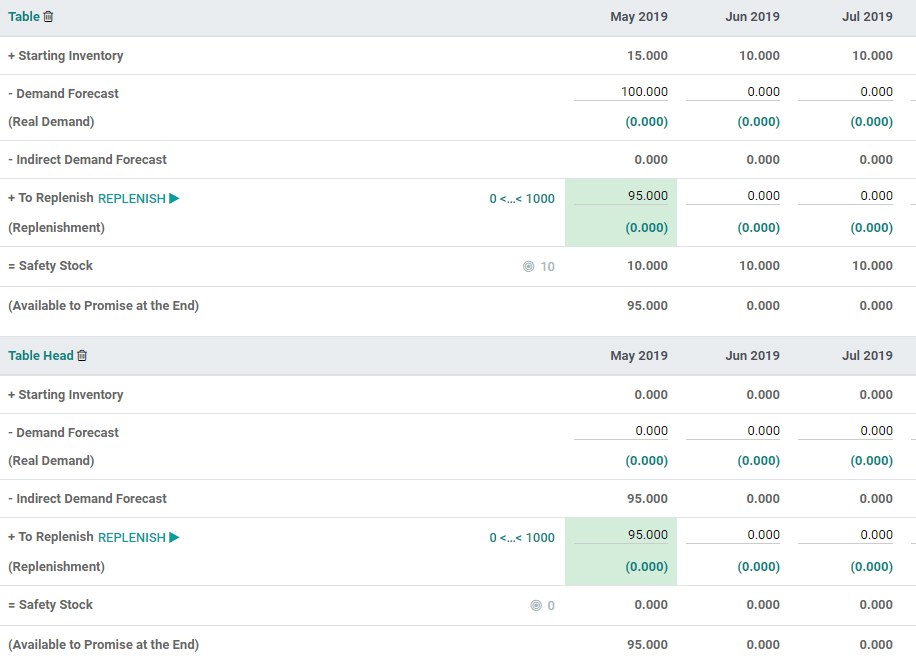

Once enabled, go to Planning → Master Production Schedule and click Add a Product. For each product:

- Set the safety stock target (desired stock level at the end of the period).

- Define the minimum and maximum replenishment quantities.

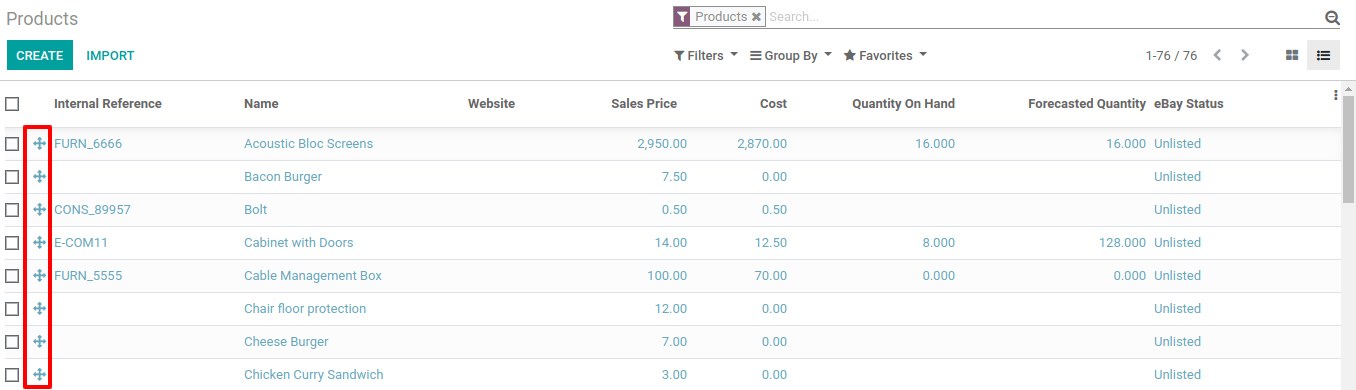

Tip: The order of products in the MPS is based on their sequence. You can rearrange them by dragging and dropping items in the product list.

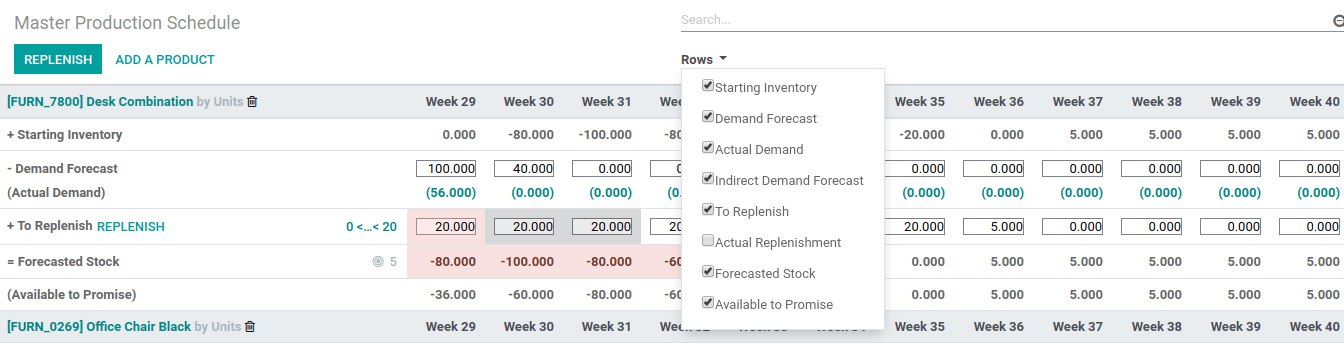

Customising the MPS View

In the Master Production Schedule (MPS) view, you can customise which information is displayed by clicking on Rows. Some key fields you can add include:

Actual Demand

Displays the quantity of products already ordered for the selected period.

Available to Promise

Helps track what can still be sold during the period (calculated as planned replenishment - already sold stock).

You can also hide unnecessary fields if they are not relevant to your production planning.

Step 2: Estimate Demand and Launch Replenishment

The next step is to estimate the expected demand for each period:

- Enter the forecasted demand in the Demand Forecast row.

- Compare the demand forecast with the actual demand (confirmed sales orders).

- The demand forecast for a finished product will also affect the indirect demand for its components.

Once the demand is estimated, Odoo will automatically calculate the required replenishment quantities. Replenishments based on lead times (vendor or manufacturing) will be displayed in green.

To launch replenishment:

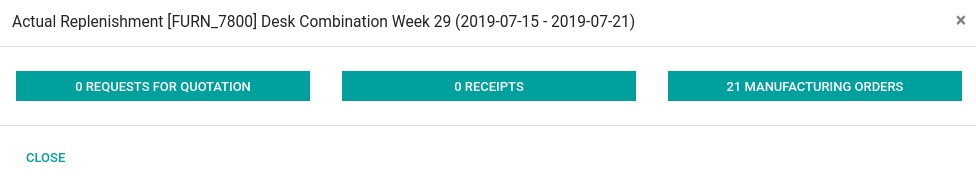

1. Click the Replenish button.

2. Depending on the product configuration (Buy vs. Manufacture), Odoo will create:

- Requests for Quotation (RFQs) for purchased products.

- Manufacturing Orders (MOs) for in-house production.

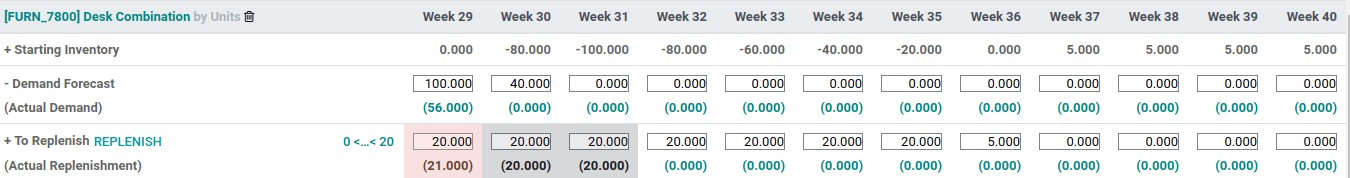

You can easily access those by clicking on the Actual Replenishment cell.

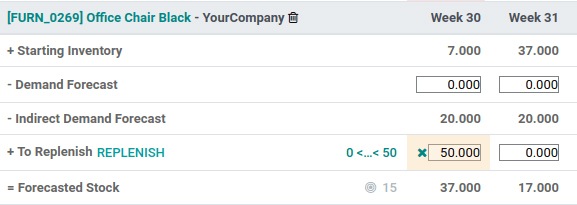

Manually Adjusting Replenishment Quantities

If you edit the To Replenish quantity manually, a small cross icon will appear. Clicking this will revert it back to the automatically calculated value.

Understanding MPS Cell Color Significations

Odoo uses color-coded cells in the MPS to indicate different replenishment statuses:

Green: The correct replenishment quantity needed to maintain safety stock.

Grey: Replenishment order already generated, and the quantity matches current data.

Red: Replenishment order generated, but the quantity is too high compared to actual demand.

Orange: Replenishment order generated, but the quantity is too low compared to actual demand.

Additionally, if a cell in the Forecasted Stock row is red, it means the stock will become negative during that period.

Handling Changes in Demand

What if I have underestimated demand?

- You can increase the demand forecast to adjust replenishment quantities.

- The cell will turn orange, and you can launch a new replenishment.

What if I have overestimated demand?

- You can decrease the demand forecast, but the cell will turn red to inform you that you’ve ordered more than planned.

- If needed, you may cancel RFQs or MOs manually to adjust for excess stock.

What if I mistakenly added a product to the MPS?

- You can easily remove a product by clicking the trash bin icon next to its name.

Wrap-Up

By leveraging the Master Production Schedule (MPS) in Odoo, manufacturers can effectively balance demand forecasting, stock management, and replenishment planning. The color-coded indicators, automated replenishment suggestions, and manual adjustment options make it a powerful tool for optimising production.

Implementing MPS correctly ensures you maintain the right inventory levels, reduce waste, and improve manufacturing efficiency.