Setting Up Routing for Kit Components in Odoo

In Odoo Manufacturing, kit components are often used within a Bill of Materials (BoM) to simplify the management of complex products. However, in some cases, the finished product and its kit components follow different routings. This means that components are consumed at different stages of production, requiring proper routing configuration.

This article explains how to set routing for kit components when they have different routing than the finished product and ensure accurate work order processing in Odoo.

Kit Consumption Set on Finished Product BoM

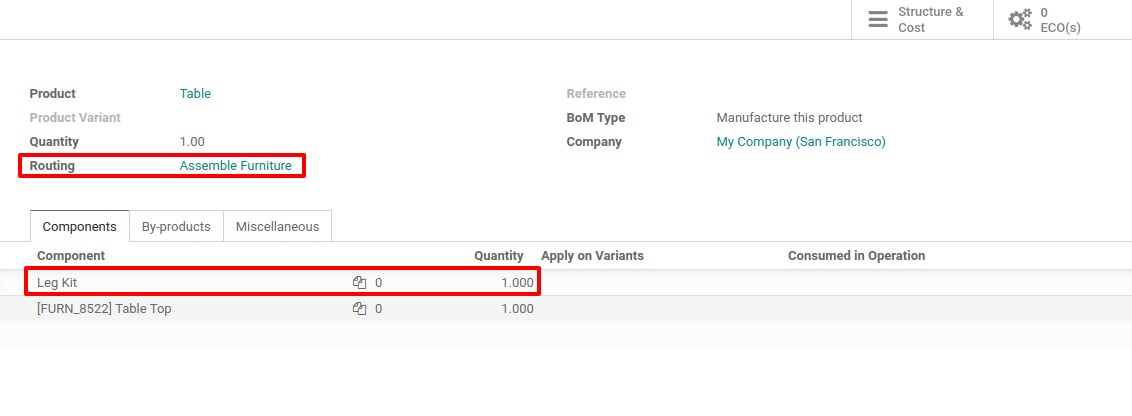

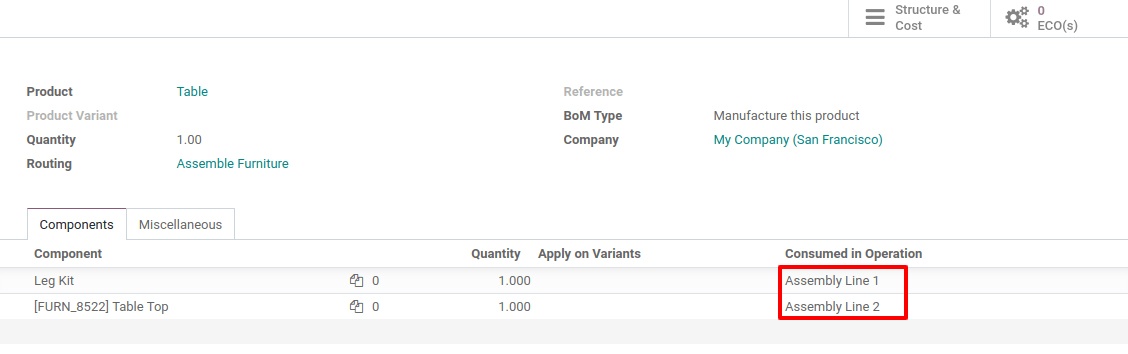

Step 1: Create a BoM for the Finished Product

- Navigate to Manufacturing → Master Data → Bill of Materials.

- Click Create to define a BoM for the finished product.

- Include the kit component in the list.

- Assign a routing (e.g., Assemble Furniture) to this BoM.

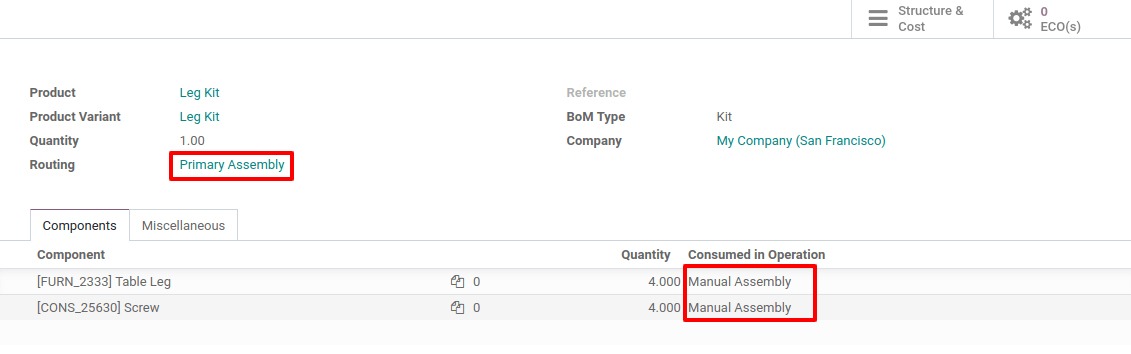

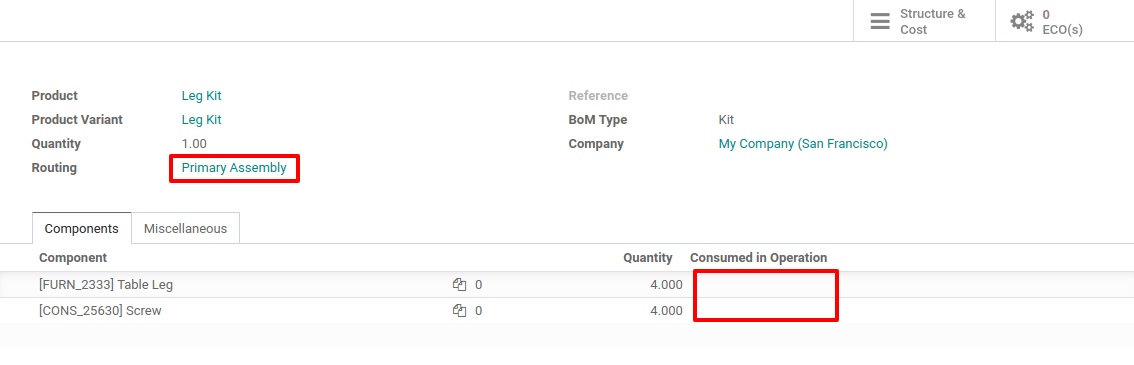

Step 2: Create a Kit BoM for the Kit Component

- Update the kit component and define its own BoM.

- Assign a different routing than the finished product.

- Specify at which operations the kit components are consumed.

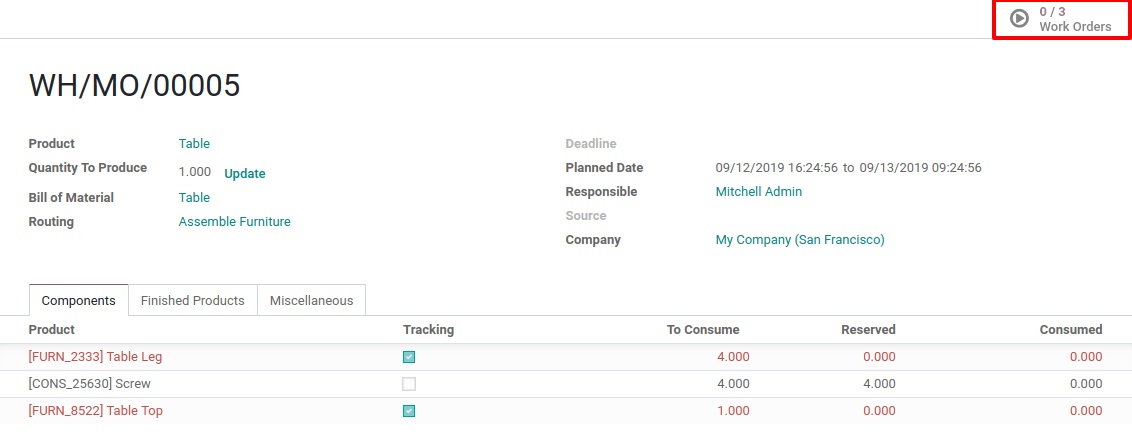

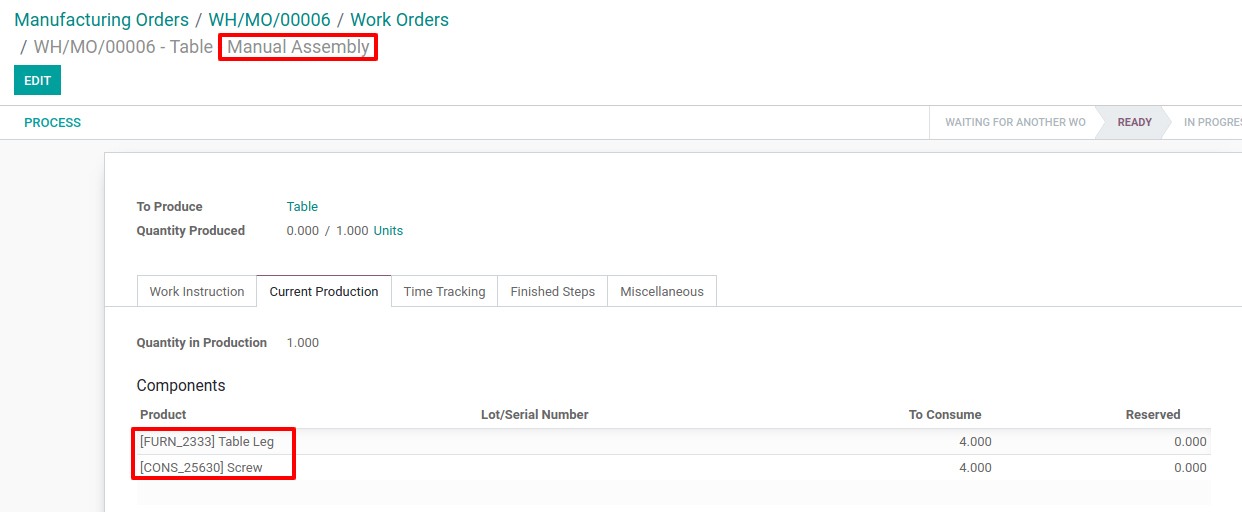

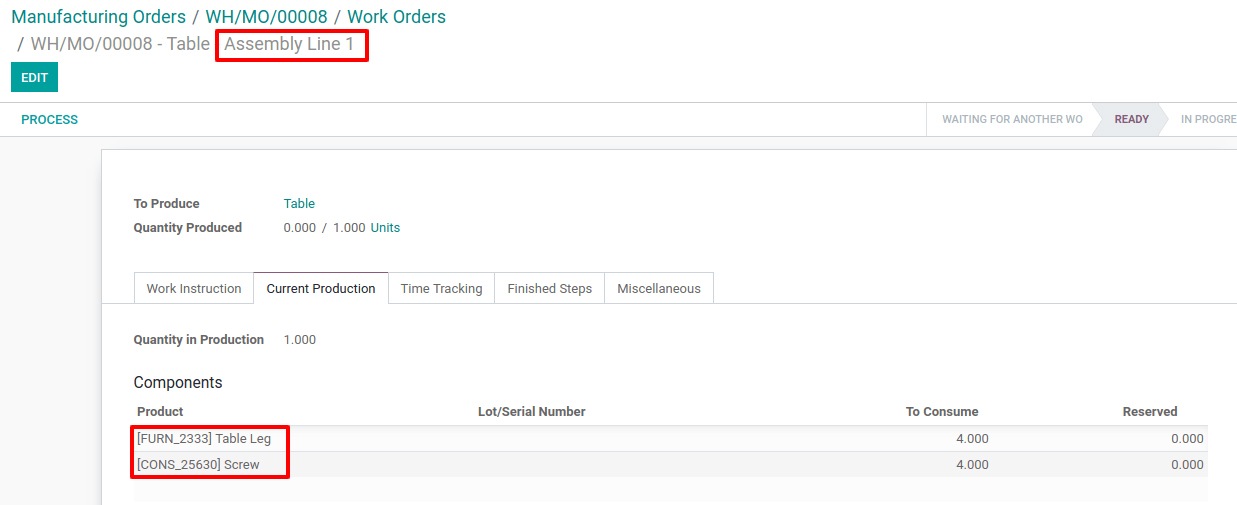

Step 3: Process the Manufacturing Order

Once the manufacturing order is created, Odoo splits the kit into its individual components. Since the finished product and kit components follow different routings, the system generates multiple work orders:

- One work order is created for the finished product based on its routing.

- Additional work orders are generated from the kit BoM’s routing.

- Components are consumed during their respective operations as defined in the BoMs.

Kit Consumption Set on Kit BoM

Step 1: Create a BoM for the Finished Product

- Navigate to Manufacturing → Master Data → Bill of Materials.

- Define a BoM for the finished product.

- Include the kit component and precisely define component consumption.

- Assign a routing (e.g., Assemble Furniture) to the finished product BoM.

Step 2: Create a Kit BoM for the Kit Component

- Update the kit component and define its own BoM.

- Assign a different routing than the finished product.

- Ensure component consumption aligns with the BoM structure.

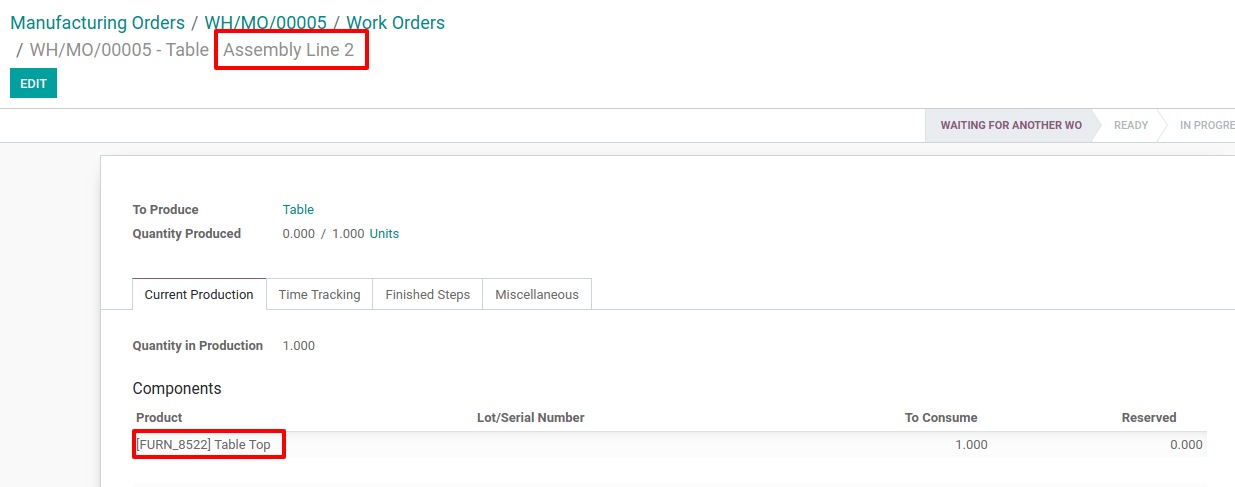

Step 3: Process the Manufacturing Order

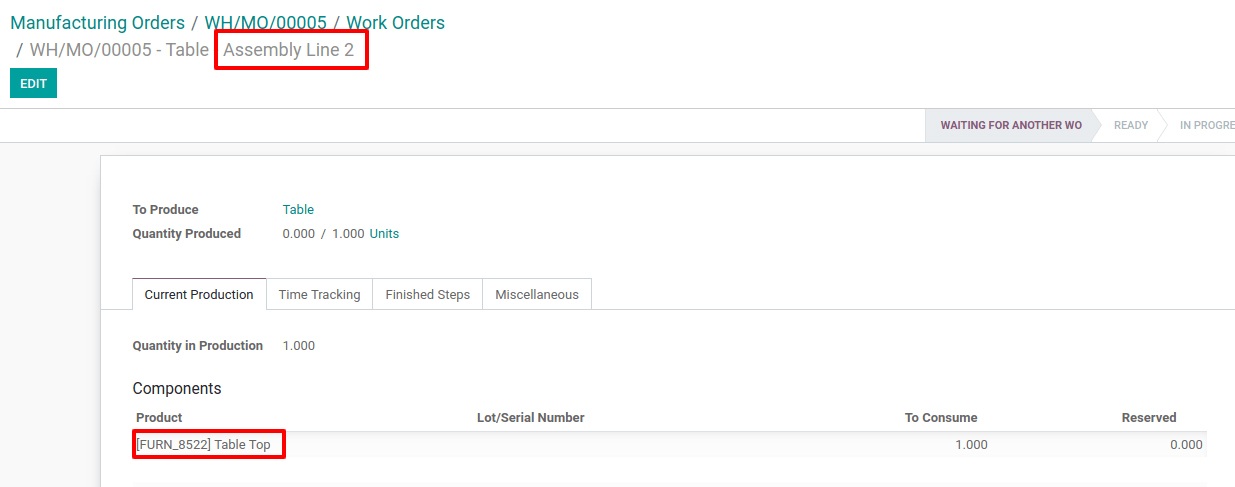

When the manufacturing order is created, Odoo processes kit components based on the defined routing. The kit is split into its individual components, and multiple work orders may be generated:

- One work order for the finished product.

- Additional work orders for the kit BoM, depending on its routing.

The timing of component consumption is determined by the routing setup. In this example, most components are consumed during the first operation, while the last remaining component is used in a later operation.

Wrap-Up

By correctly setting routing for kit components with different routings, manufacturers can ensure that components are consumed at the right stages of production. Odoo automates work order generation, optimising manufacturing efficiency and ensuring smooth operations.